HOW DOES A PIANO ACTION WORK?

A piano action is an amazing mechanism with an enormous responsibility. Its crucial task is to transfer musical energy seamlessly from the pianist’s fingers to the piano strings, allowing the player to accurately and expressively communicate the subtle (and not so subtle) musical nuances of the heart and mind through the instrument and into the listener’s ears. Achieving that “seamless transfer of energy” without compromise is a tall task, indeed. To accomplish it properly, all 8000+ parts of the piano action must remain stable and work together perfectly at all times – over the course of time. Even the smallest dimensional or positional change in any component part can hurt piano performance by preventing the action mechanism from working properly. When problems occur, the player will sense the loss of optimal tone and touch. Performance suffers – and the music produced will be far less satisfying for player and listener than it could have been.

There is a way to prevent dimensional changes and instability in a piano action. But first, it will help to understand how a piano action works.

THE BIG PICTURE

When a piano key is pressed, a corresponding hammer rises to strike the string (or strings) causing the highly-tensioned strings to vibrate. The energy of the vibrating string is transferred to the soundboard through a component called the “bridge” that is fixed to the top of the soundboard. Because the soundboard is mounted with tremendous tension (similar to the tensioned head of a drum), it resonates intensely when sound energy is received. It is the resonating vibrations of the soundboard that a listener hears as “tone” when a piano is played.

This “big picture” description may be sufficient for most people to understand how a piano action creates sound. But there are many intermediate steps that take place as the hammer prepares to strike the string.

THE INNER WORKINGS

When a grand piano key is depressed, the other end of the key lifts upward with equal force. This key movement lifts a screw known as the “capstan.” The capstan is located under a multi-faceted hinged assembly called the “wippen” that contains an L-shaped part called the “jack.”

The upward force of the capstan causes the wippen to rise, thrusting the jack upward into another component called the “knuckle” that is fixed to one end of the hammer shank. As the knuckle and hammer shank are forced upward, the felt hammer (that is fastened to the other end of the shank) is propelled toward the string to create the hammer strike. From this description, one can see that the flow of energy from “a key being pressed” to “a string being struck” is actually an intricate series of progressive steps that lead to the ultimate hammer strike.

CREATING TONE

The hammer strike, however, is only the beginning of the process for creating piano tone. The hammer must bounce off (or “release”) from the string immediately so the strings can vibrate. This hammer release must occur even if the player holds the key down. Without this release, the hammer would remain pressed against the strings, muting any tone that may be created and producing only a dull “thud” instead of resounding tone. What makes this hammer release possible? As the jack raises the knuckle, it engages a component called the “let-off button” that causes the jack to release from the knuckle at the precise moment before the hammer hits the string. This “let-off” allows the hammer to fall away so the strings can vibrate freely after the strike.

THE PROBLEM OF REPETITION

But the hammer release presents another potential issue. What if the player wants to repeat the same note immediately? If the hammer drops all the way down to its initial rest position, it would take too long to reset and play a quick repeated note. To solve this problem, the end of the key (which is inside the piano and can’t be seen) is fitted with a component called the “backcheck” that rises as the key is pressed and catches the hammer as it rebounds from the string. The raised backcheck holds the hammer just under the strings awaiting the possibility of another strike. If the note is repeated, the key only needs to be raised slightly for the jack to reset for another immediate strike. This inventive design makes a series of rapid repeated notes possible.

MAKING THE TONE STOP

But there is one more problem the action must solve. The pianist must be able to not only make notes sound, but also make them stop sounding. When a key is not being played, a component called the “damper” rests on top of the corresponding strings to prevent them from resonating with other vibrating strings (a phenomenon called “sympathetic vibration”).

When a key is initially pressed, the other end of the key pushes up on a component called the “damper lever” which immediately lifts the “damper felts” off the strings for that note. (You can now see that two things must occur simultaneously to keep a string vibrating – the hammer must release and the damper must be raised). While the key remains pressed down, the damper hovers above the strings allowing them to vibrate. When the player releases the key, the damper falls back down onto the string to silence it. In this way, the damper mechanism allows the player to control the length of each note.

In addition, the pianist can also use the “damper pedal” below the keyboard to lift all dampers at one time. The damper pedal is also called the “sustain pedal” because it allows the sound of all notes to be sustained (or continually resonating) at the same time. When the damper pedal is released, all dampers fall and the sound stops for all notes (except those that are still being sustained by keys that are depressed).

THE CRITICAL IMPORTANCE OF STABILITY

While the preceding paragraphs may seem thorough, they represent only the “tip of the iceberg” in trying to describe all the intricate workings of a piano action. A complete description would demand countless chapters of additional text. The point is that a piano action is a marvelously multifaceted mechanism that requires thousands of individual components and processes to work together perfectly – every time, over time – to allow the pianist’s musical intentions to be transferred accurately and artistically through the instrument. The failure of any part or process can disrupt the player’s intentions and damage musical performance.

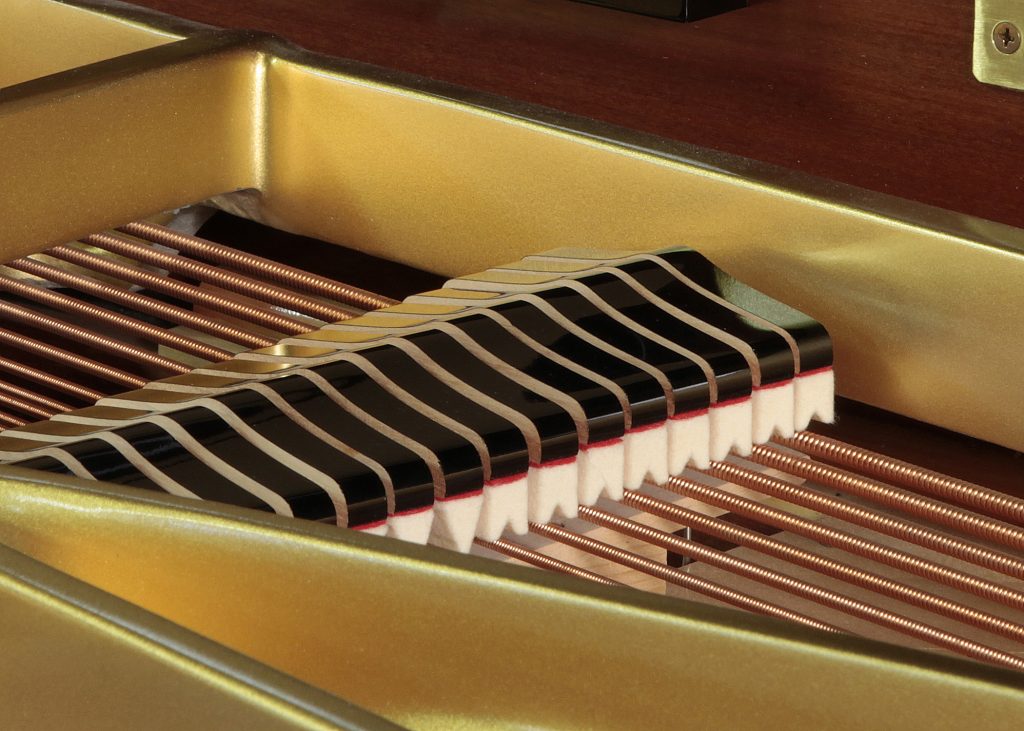

That’s why Kawai introduced composite action parts over 50 years ago. Kawai design engineers realized that using only wood for the mechanical parts of a piano action was risky. Wooden parts would continually shrink, swell and warp with changes in humidity – and those dimensional changes would alter the precision and stability of the action and hurt the player’s performance. Even the slightest change in the size of a part or its precise position in relationship to other parts will affect both piano tone and touch. For example, if the shrinking or swelling of any component causes the position of a hammer to be misaligned by as little as one millimeter, the tone and touch of a note will be compromised. The hammer may strike just two strings instead of three, reducing tone production. It may “partially strike” one of the strings, which can produce troublesome “buzzing” sounds. Or the hammer may drift even further from its ideal position and rub against other hammers making the piano’s “touch” feel unnatural, or even causing hammers to get stuck.

With all these potential problems in mind, Kawai design engineers decided that using “all wooden parts” for the piano action was a disservice to the pianist. Since 1970, Kawai has invested millions of dollars to create piano actions with composite materials, including leading-edge carbon fiber. Because composite action parts are virtually impervious to shrinking, swelling or warping due to humidity, they remain extremely stable over time. When compared with wooden parts, composite action parts are far less likely to fall out of position or negatively affect the operation of other parts when humidity levels change. This makes Kawai piano actions more stable and consistent than others, which helps pianists perform better. When the action is stable, all the magnificent musical passion and nuance delivered by the pianist flows faithfully through the instrument – without loss or deviation – to create music that fully communicates the intentions of the player. In the world of the piano, stability creates beauty.

The revolutionary Millennium III Grand and Upright Actions with carbon composite parts are prime examples of Kawai’s passionate commitment to innovation – and proud symbols of the company’s 90-year legacy of creating great instruments that enable pianists to fulfill their highest musical aspirations.

FEATURES OF THE MILLENNIUM III ABS-CARBON ACTION

In the beginning was the conventional wooden piano action. It evolved through three generations – and it was good. The 1980s brought the fourth generation of the piano action, the Kawai Ultra-Responsive ABS Action – and it was much better.

Now, you can experience the fifth evolution of piano touch – the revolutionary Millennium III Action with carbon composite parts.

ABS-Carbon Action Parts

The Millennium III Action features components made of ABS-Carbon, a new composite material created by the infusion of carbon fiber into our existing ABS Styran. ABS-Carbon is incredibly sturdy and rigid, which allowed Kawai to make the action parts lighter without sacrificing strength. The lighter design makes the Millennium III Action tremendously fast and effortless for the player. The repetition and responsiveness are superb.

Micro-Engineering

Every detail of the action was exhaustively analyzed to meet the stringent demands of the skilled pianist. One prime example of this effort was the addition of microscopic surface texture on the jack at the point where it meets the knuckle. The result of this subtle but important change is a dramatic increase in control during pianissimo playing.

Key Benefits

Strength: Adding carbon fiber to our renowned ABS-Styran parts increased strength by 90%. This enabled ABS-Carbon parts to be stronger, even though they were made lighter in weight.

Speed: With lighter ABS-Carbon parts, the Millennium III Action is approximately 25% faster than a conventional wooden action.

Power: ABS-Carbon is more rigid and sends more energy to the hammer with every keystroke,

providing more power with less effort.

Control: The jack is redesigned with a microscopic surface texture to provide unparalleled control

for pianissimo playing.

WHY YOU NEED A MODERN PIANO ACTION

View this important video to see how composite materials have transformed piano performance and how every pianist will benefit from the Millennium III Action with carbon composite parts.

Here’s a surprising piano fact: The component that contributes most to a piano’s overall success and performance is seldom, seen by those who play it. That critical component is the piano action. Hearing that, the immediate question from most pianists is: “What on earth is a piano action?” After all, most pianists have spent a lifetime playing pianos without ever seeing what’s inside that makes them tick. For the piano buyer, failing to appreciate or fully comprehend the vital importance of a well-made piano action is a grave mistake – one that could negatively affect the player’s musical enjoyment for many years to come.

The “action” is the mechanism inside a piano that transforms the player’s touch on a key into a hammer strike that produces musical sound. Modern piano actions are often composed of over 8000 individual parts that all work together to translate the subtle movements of the fingers into expressive music that inspires.

Back in the early 18th century, an Italian inventor named Bartolomeo Christofori created the first piano action. An ingenious departure from the pre-existing harpsichord action that “plucked” the strings and offered a limited range of tone and dynamics, Christofori’s piano action featured hammers that “struck” the strings and provided a much wider range of volume and expression. It was a great start, but quite primitive and not very stable.

In the 19th century, French piano maker Sebastian Erard developed a piano action that was a major evolution from “old” to “new.” Erard’s “double escapement” design allowed the player to quickly repeat a note without fully releasing the key. It offered greater possibilities for composition and performance, but still didn’t address the issue of stability.

Both of these early action designs were made entirely of wood. That’s because wood was the only material the early piano makers had available to craft the thousands of intricate parts needed for the action.

The first half of the 20th Century brought even more evolution. Many piano actions of that period were based on this design (right) which was also made of all wooden action parts.

These actions promised higher performance and better control of touch and tone. Yet, the stability problems remained.

Then, at the halfway point of the 20th Century, something surprising happened in the piano industry. After 250 years of steady progress in the art of the piano, evolution stopped. Progress came to a virtual halt. It was as though piano makers believed that a piano couldn’t get any better.

Meanwhile, other industries kept evolving rapidly. In the tennis world, manufacturers of wooden rackets began moving to composite materials (such as graphite, kevlar and eventually carbon fiber) to improve racket performance. By the 1980s, wooden tennis rackets were obsolete.

The golf industry made a similar move away from traditional wood drivers to other materials that could provide a longer, more stable tee shot. Wooden drivers became “relics of the past” as golf moved on to modern materials.

While these and other industries kept advancing, piano makers seemed content to maintain the status quo, except for one – KAWAI.

As early as the 1960s, Kawai craftsmen recognized the serious problems associated with wood. Wood was ideal for many of the “sound-producing” components of a piano (such as the soundboard, rim and hammers), but it was problematic for many of the major internal components of a piano action.

The problem? Wood wasn’t stable. It could break under high stress and would continually swell and shrink with changes in humidity. With the many thousands of individual parts in the action, these shortcomings were unacceptable. Kawai design engineers knew that the mechanical parts of piano action required exacting and unchanging precision – and that wooden parts could never maintain that level of precision over time. With that in mind, they set out to solve a major wood-related problem: the flawed hammer strike.

To create excellent tone and touch, the hammers must strike the strings perfectly every time, over the course of time. If the alignment of the hammer is altered, even by as little as one millimeter due to breakage or the swelling or shrinking of any component, the piano’s tone and touch deteriorates and the player’s enjoyment and performance fades.

To solve this problem, Kawai invested millions of dollars to develop action parts made of composite materials. First introduced in 1970, Kawai composite parts are more durable than wood and virtually impervious to swelling and shrinking due to humidity.

By the 1990s, these efforts resulted in the Kawai Ultra-Responsive Action – the fourth major evolution of touch and tone in the history of the piano.

With composite parts, Kawai actions were far more stable than conventional all-wooden actions. Kawai hammers would strike the strings with greater precision despite changes in humidity. And Kawai pianos maintained better touch and tone over time than any other pianos. By the end of the 20th Century, Kawai had established itself as the technological leader in the global piano industry.

But evolution didn’t end there. Kawai continued to evolve into the 21st Century with the introduction of carbon composites to improve piano touch and responsiveness. As carbon fiber found its way into modern aircraft, race cars, racing boats and performance cycling, it also played a major role in the development of Kawai’s revolutionary Millennium III Action with ABS-Carbon parts.

The lighter weight and tremendous strength of carbon fiber made possible advances in playing speed, power and overall control for the player. The Millennium III Action launched the “5th Evolution” of the piano and positioned Kawai two generations ahead of others who continued to build conventional wooden actions.

Today, nearly fifty years after its historic introduction of composite parts in piano actions, Kawai continues to be the leader of innovation in the piano world. Now the recipient of over 50 major international awards for excellence, Kawai is proud to be a three-generation, family-run company with a steadfast commitment to evolution and technological advancement that will continue for years to come.

With all this in mind, the wise piano buyer should reflect deeply on the following questions:

- Do you want the undeniable benefits of modern piano technology?

- Do you want excellent tone and touch that will last?

If your answers are yes, your next piano should be a KAWAI.